ReFreeDrive project is getting into its final months. As the project goes forward, prototypes manufacturing activities are progressively reaching to their end and testing activities are gaining more and more relevance at all scales: motor testing, powertrain integration tests and, last but not least, in-vehicle testing.

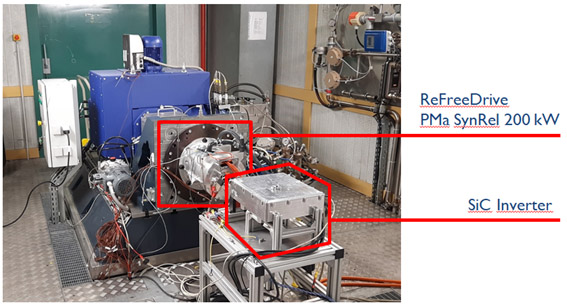

Motor testing involves all in-bench testing activities that allow assessing the performance (torque/speed and efficiency maps) of the different motors developed within the project, as well as evaluating the accomplishment of the target KPIs. Up to now, tests carried out at IFPEN, R13 and University of L’Aquila on synchronous reluctance motors (pure and permanent magnet assisted, for both 75 kW and 200 kW power levels) confirm that the prototypes meet the expected design performances, which gives us full confidence to face the induction motors testing campaign.

Once the motors are characterized, the next step which is currently ongoing at Cidaut is the full powertrain testing. In these tests, the objective is to gain knowledge on the interaction between the motors and other powertrain components, to ensure that the whole system runs smoothly, and to correct all potential issues that may arise before proceeding to the last testing stage out of the labs.

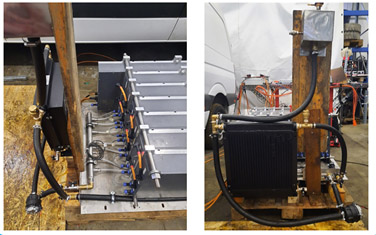

In parallel, several in-vehicle integration activities are under progress at Privé facilities, aiming at manufacturing, adapting and assembling all the different vehicle subsystems, such as battery pack or cooling, previously to the installation of the motors, to be in optimal position to make the final circuit demonstration.

In the upcoming weeks we will share more interesting content about the project, so stay tuned!

Comentarios recientes