Structure

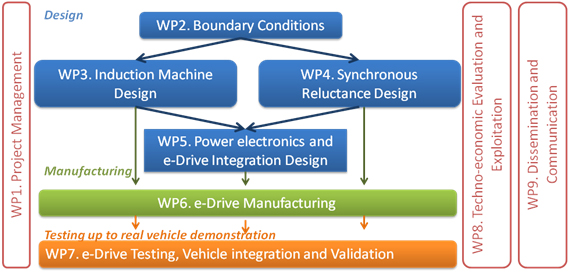

ReFreeDrive main objective is to research and develop new electric drives based on free of rare earth technologies, namely induction machines (IM) and synchronous reluctance machines (SynRel or PMa SynRel). In order to develop and integrate the new powertrains for a final in-vehicle validation for two use cases (75kW, medium power range, and 200kW high power range), the project has been structured in nine different work packages, as seen in the following figure.

There are three transversal work packages that will take care of steering the project, evaluating its results and making sure these results are widely known and can be exploited efficiently. These work packages are: WP1, Project Management; WP8, Techno economic evaluation and exploitation, which will overseeing the main results in terms of performance and cost, and studying the steps to take the achieved results to the mass production market; and WP9. Dissemination and Communication, which will ensure a fluid communication with specific content is created between the project and the identified relevant audiences.

In terms of the project technical development, the work to be done will be split into design work packages, a manufacturing work package and a final testing work package.

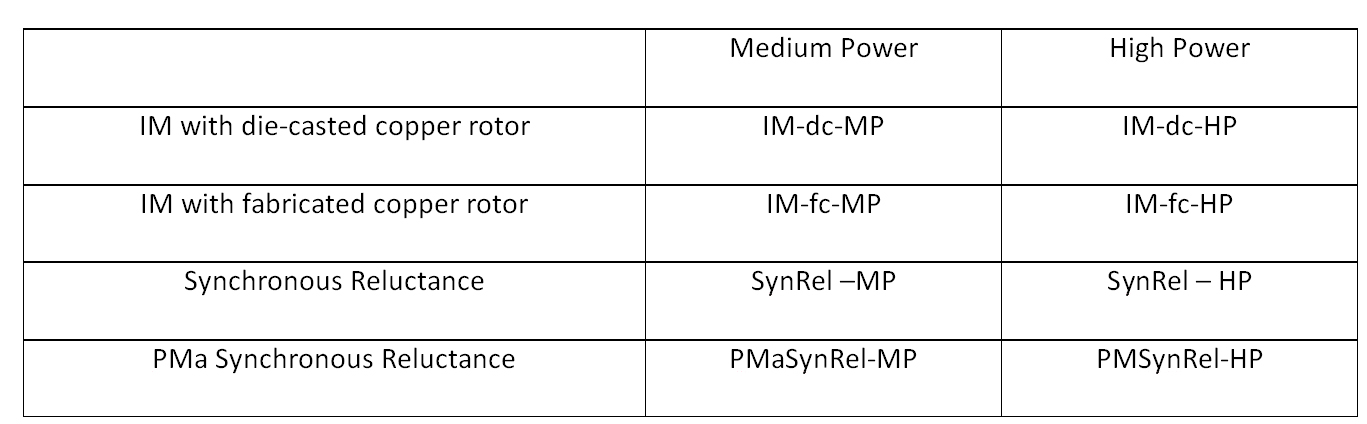

The design work packages will start from defining in detail the boundary conditions (WP2), the reference framework under which the project designers will operate, and which will have to include requirements from the end users, manufacturing limits and restrictions from the project manufacturers and how these can be translated to useful design measures. Two work packages will run in parallel to study the technologies already mentioned above: WP3 will focus on IM design featuring copper rotors, either fabricated or die-cast, and WP4 will focus on SynRel Design, either pure (no permanent magnets) or with ferrite permanent magnets (PMa SynRel). Both work packages will design traction machines for both end users, resulting in the following definition of project tracks:

WP5, the final design work package will research and develop the power electronics and control strategies needed for each power range. This means that both traction technologies will share the same power electronics and control algorithms in each use case (medium power range, high power range). Besides, the WP5 will analyze and select off the shelf solutions for the rest of the powertrain systems needed from an integration point of view, such as batteries, gear box, electric and electronic integration as well as cooling systems and testing systems.

WP6 will be in charge of prototyping the e-Drives. This project features low cost manufacturing as one of the features new e-Drives should have in order to be competitive in a global market. Therefore, a full work package has been devoted to make sure manufacturing decisions, upscaling and industrialization issues are taken into account in time.

WP7 will test the developed e-Drives. These tests will be carried out incrementally: starting from standalone tests of the e-Drives and integrating all the systems first on a test bench, the final outcome from this work package will be two vehicles (based on Gladiator Evolution or Jolly 2000) in which the developed e-Drives have been integrated and driven for a real use case demonstration.