From September 29 to October 3, 2019, the eleventh Annual IEEE Energy Conversion Congress & Exposition (ECCE 2019) will be held in Baltimore, Maryland (USA). IEEE ECCE shares an insight into the recent research and cutting-edge technologies in electrical and electromechanical energy conversion, being the world’s leading technical conference and exposition for energy conversion solutions. Exhibitors at ECCE showcase state-of-the-art technologies, products and solutions, hence creating a highly interactive networking environment. You can get more information about the event in the following link: http://www.ieee-ecce.org/2019/

The partners of the ReFreeDrive Project will present their latest progresses in the design of both sychronous reluctance and induction motors. Two conference papers have been submitted, which are briefly described below.

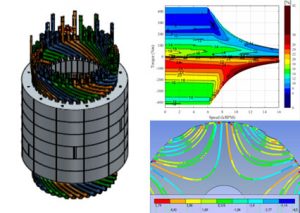

Title: A Copper Rotor Induction Motor Solution for Electrical Vehicles Traction System

Authors: Mircea Popescu, Nicolas Rivière, Giuseppe Volpe, Marco Villani, Giuseppe Fabri, Lino Di Leonardo

Abstract: This paper deals with the design of a scalable 200kW/370Nm or 75kW/200Nm, induction machines for electrical vehicles traction system. Two configurations are considered as low cost rare-earth free magnet electric motor alternatives: inner rotor and outer rotor. Both designs allow mass production while providing higher performance compared to current technologies. The electromagnetic, thermal and mechanical constraints are considered throughout the machine design, from the specifications to the optimization. Rotor diecasting, oil spray cooling and hairpin stator winding are used in the analyzed solutions. Analytical and numerical methods are used for electromagnetic and continuous thermal performance calculation over the full speed range of the machine, along with the mechanical limits from a stress and modal point of view.

Title: Synchronous reluctance motors with asymmetric rotor shapes and epoxy resin for electric vehicles

Authors: Andrea Credo, Marco Villani, Mircea Popescu, Nicolas Riviere

Abstract: This paper deals with the design of a Synchronous Reluctance motor for full-electric vehicle applications. In particular, the design is focused on premium vehicles and aims at the development of rare-earth free electric motor technologies featuring low cost manufacturing. Different solutions are proposed and compared with focus on the rotor design; the investigated topologies employ asymmetric rotor structures with “fluid shaped” barriers without radial ribs to maximize the average torque and minimize the torque ripple. As this choice is very critical for the mechanical strength of the rotor core at high speed, it has been decided to fill the flux barriers with epoxy adhesive resin. The use of the resin has required an accurate mechanical analysis in order to assess the rotor robustness at high speed. The paper presents the performances of the optimized design and the efficiency and torque ripple maps: moreover, useful information on the use of the epoxy resin in the synchronous reluctance motor is provided.

Comentarios recientes